Materials 4.0: Three state-of-the-art surface modification techniques for your industrial components

At the moment, Basque business is living through times of change and experiencing an unusual and difficult situation. Times of crisis are also times of opportunity, as a manager you may be considering whether in the midst of this current situation improvements can be made to your manufactured products, and in particular, to their finishes.

Maybe a specific need has been identified during the stoppage of industrial activity, or perhaps because the Production Manager has decided that the company needs once and for all to improve the performance of the materials it uses today, in the face of increasingly demanding service requests, and to find and apply new, more effective and durable coatings.

This article details 3 techniques for modifying leading surfaces, which make it possible to significantly improve the characteristics of manufactured parts in aspects such as resistance to external agents (oxidation, corrosion, etc.), optimisation of friction and durability, and resistance to wear and tear, among others. Such techniques are relevant for the Managers, or Heads of R&D, Quality or Production from companies that manufacture industrial components, in the automotive, metalwork, aerospace or energy sectors to make decisions about which ones to explore and introduce in the company.

The first technique presented is laser texturing; the second covers coatings and wet finishing processes to obtain high added-value surfaces; the third focuses on surface solutions using PVD technology (Physical Vapour Deposition).

These techniques can be implemented thanks to the combination of a series of assets and experts in the field that we have in the Basque Country, brought by the SPRI Group together with the BDIH, and its Advanced Materials Node.

Laser texturing allows the properties of a material to be changed thanks to the textures that can be engraved on the material itself or onto the injection mould. In this way, products are given greater customisation and added value through their functionalisation as part of conventional production processes. This method is provided by several members of the node through their BDIH service offering, for example CEIT has an active Photonics Unit for functionalisation and heat treatment of surfaces with ultra-short pulse and interference lasers. This unit means that Basque companies can benefit from two femtosecond lasers to develop surface structuring processes with nanometre precision and generate embedded microsensors, to deposit thin and thick films by means of CVD (Chemical Vapour Deposition) or carry out very high precision micromachining and microcutting processes.

On the other hand, Azterlan provides surface modification services for castings and has a purpose-built experimental pilot plant for casting iron, aluminium alloys, superalloys, steels, high entropy materials, etc. in vacuum or under different atmospheres, to create new alloys and manufacture prototypes.

For its part, TECNALIA, from its Nano and Surface Micro-texturing Centre, allows companies to obtain benefits from techniques such as NIL (lithographic nanoimpression) and to copy the shape by modular injection or thermoforming. The services offered by this asset, allow to experiment with different techniques for the manufacture of mouldings with micro nano textures (chemical engraving, plasma engraving…), the selection and development of surfaces working different functions: superhydrophobic, superhydrophilic, structural colours, aesthetic, anti-reflective, anti-fog, anti-frost… and the manufacture of inserted/molded micro nano texturized and development of processes by texture reproduction.

The second technique of interest to Basque SMEs is the Wet Finishing process. Wet Finishing consists of developing thin coats of finishing in the presence of an aqueous or organic medium with the thickness of the layers controlled according to the type and conditions of the process used.

CIDETEC provides its pilot plant and lab to BDIH clients for the application of wet coatings. It is fully equipped for the finishing of (electro) chemical surfaces and application of protective ceramic coatings. CIDETIC also the means for printing on rigid and flexible materials and is capable of carrying out sol-gel coatings. This asset offers several services: deposition of functional coatings (e.g. corrosion protection, easy cleaning by anti-static and/or omnifocibility); development and application of metallic, ceramic, composite and hybrid coatings; preparation, polishing and chemical cleaning of surfaces; application of ceramic coatings on different types of metallic substrates in order to provide improved properties to these surfaces, and screen printing which consists of the application of conventional and/or functionalised ink coatings on different types of materials such as metal, insulators and semiconductors.

The third and last surface modification technique available in the Advanced Materials node of the BDIH is PVD (Physical Vapor Deposition). This is a vacuum coating process that produces a decorative and functional glossy finish. PVD uses a titanium nitride which provides an extremely durable coating and PVD coatings are more resistant to corrosion by sweat and regular wear than gold plating.

Tekniker has a pilot PVD coating production line for industrial components, which offers 8 different PVD technology coating manufacturing equipment at industrial level, covering cathodic arc, magnetron sputtering and HIPIMS (High-power impulse magnetron sputtering or spraying of high-powered impulse magnetrons), depending on the application or industrial demand. This asset is capable of developing decorative metal coatings for plastic components, tribological coatings for mechanical components and selective coatings for solar collectors and reflectors.

It is important to highlight that other members of the node such as CIC Energigune and UPV-EHU work at a fundamental level generating knowledge in the modification and characterization of surfaces and in the process and characterization of materials at a surface level respectively.

If you are interested in deepening your knowledge of what the Advanced Materials Node of the BDIH offers, follow this series of articles on Materials 4.0 where we tell you in detail which are the capacities, assets and services of the node in a practical, applied way.

Contact the BDIH to find out how we can bring your company closer to the solutions that interest you most.

Related news

SMARTPM and SubAero Precision Machining announce strategic partnership in India

The collaboration between SMARTPM and SubAero Precision Machining (Group Designcell) is a big step in our global growth, helping us establish a strong foundation in one of the world's fastest-growing industrial markets

Companies with greater gender equality perform better in terms of innovation and are more competitive

The study of the SPRI initiative "Women in Industry" shows that gender equality has an impact on the improvement of company results.

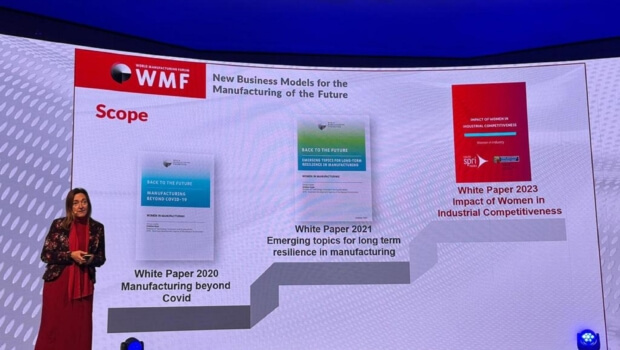

SPRI presents the results of the study on the impact of women on industrial competitiveness at the World Manufacturing Forum

The reports is the continuation of the work carried out by the SPRI Group and the Foreign Network office in Milan since 2020 as leader of the Women in Manufacturing expert group.

Europako fabrikazio-ikerketaren etorkizuna

Donostian, egunotan, MANUFUTURE Conference 2023 egiten ari da, hau da, fabrikazio-industriaren etorkizunari buruzko Europako konferentzia.

Basque Open Industry will show Europe its industrial and technological ecosystem at the European SME Week (SME Week) from 13 to 17 November.

Talent, internationalisation, energy-environmental and technology-digital transitions. SME Week 2023. Exhibition and stands at the BEC: “Rebuild Ukraine”.