Cell “Zero Defect Manufacturing”: a highly versatile solution for the metrological field

The “Zero Defect Manufacturing” Cell is one of the assets incorporated into the BDIH at the Flexible and Collaborative Robotics node. It is the property of CEIT, a technology centre whose main task is to carry out industrial research projects in close collaboration with the R&D departments of companies.

This asset consists of a flexible cell in which different technologies can be tested, all of them oriented to product inspection, such as metrology and structural integrity using 2D and 3D optical techniques or inspection by non-destructive testing (NDT) analysing magnetic properties. Additionally, allows programming, incorporation and adaptation of automation and robotics to the inspection and measurement process.

Using artificial vision techniques and NDT is possible to analyze the data of the dimensions and structural integrity of the produced parts and it also allows in-line inspection of the parts, ensuring the concept of zero-defects and in this way reducing rejection and increasing productivity.

This cell has the ability to test and incorporate industrial robots and automation to provide inspection with the necessary flexibility, For this purpose, it has 2 Fanucs robots of different dimensions and capacities. For inspection, telecentric optics are available in different sizes, for high-precision 2D inspection and several laser scanners for 3D metrology. As for the NDT, it consists of several proprietary systems for measuring magnetic properties for the detection of grinding burns and the creation of a hardness map of the product.

The demands of the different types of inspection require tasks where contact force control is required (inspection with non-destructive sensors requires precise probing) in addition to the classic approach to traditional precision-positioning robotics (dimensional inspection). In anticipation, these robots have force sensors that allow us to see what effort the robot is making in the event of a contact with the surface.

This asset, which we present within the BDIH Robotics Month, makes available to companies a flexible cell with the ability to characterize a product, it has two important benefits: the first, the generation of a detailed report of the product, including metrological levels, defects, hardness map; secondly, it enables the testing and validation of technologies in which the customer may be interested, as this cell is versatile enough to test different configurations and study the viability of a specific technology. This versatility feature allows the process to be configured with the required stations, as well as the technology to be used in each station.

Related news

SMARTPM and SubAero Precision Machining announce strategic partnership in India

The collaboration between SMARTPM and SubAero Precision Machining (Group Designcell) is a big step in our global growth, helping us establish a strong foundation in one of the world's fastest-growing industrial markets

Companies with greater gender equality perform better in terms of innovation and are more competitive

The study of the SPRI initiative "Women in Industry" shows that gender equality has an impact on the improvement of company results.

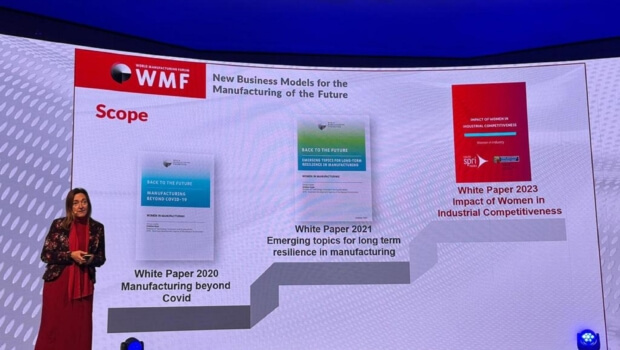

SPRI presents the results of the study on the impact of women on industrial competitiveness at the World Manufacturing Forum

The reports is the continuation of the work carried out by the SPRI Group and the Foreign Network office in Milan since 2020 as leader of the Women in Manufacturing expert group.

Europako fabrikazio-ikerketaren etorkizuna

Donostian, egunotan, MANUFUTURE Conference 2023 egiten ari da, hau da, fabrikazio-industriaren etorkizunari buruzko Europako konferentzia.

Basque Open Industry will show Europe its industrial and technological ecosystem at the European SME Week (SME Week) from 13 to 17 November.

Talent, internationalisation, energy-environmental and technology-digital transitions. SME Week 2023. Exhibition and stands at the BEC: “Rebuild Ukraine”.

Get to know the assets of the BDIH: 5-axis multi-process milling cell, capable of very high speed operations

The University of the Basque Country offers Basque companies, via the BDIH, the possibility to have at their disposal a 5-axis multi-process milling cell, capable of very high-speed operations.

Get to know the assets of the BDIH: Inspection/measurement robotic cell using non-destructive techniques

Tekniker gives the opportunity to Basque companies, by means of the BDIH, of having at their disposal a cell which permits to carry out analysis for the quality control and the non-destructive inspection of pieces.

Get to know the assets of the BDIH: Equipment/Techniques/Methodologies for the study and evaluation of corrosion

Cidetec offers Basque companies, through the BDIH, the possibility of testing their materials with in the order to know their corrosive capacity. For this purpose, the asset uses accelerated and cupro-acetic corrosión climatic chambers, as well as electrochemical and localized techniques for the corrosion studies.

Get to know the assets of the BDIH: Systems for mechanical properties and microstructure determination by magnetic non-destructive measurements

CEIT offers companies, through the BDIH, the possibility of access to quality control systems to detect failures or inspect subsurface processes in a non-destructive manner, allowing costs to be reduced and avoiding wasting parts that could be sold

The Enterprise Europe Network offers Basque companies advice on technological development and the international commercialization of innovative products and services

The Enterprise Europe Network (EEN) has established itself as the perfect public sector tool to complement the efforts of Basque companies in internationalizing their R&D&i and their business in general. Through its advisory and assistance service in the transfer of knowledge, technology and innovation, more and more SMEs are seeing...