Intelligent and connected machines: Achieving value-add through improved Digital Finishing

Grupo SPRI presents the node of Intelligent and Connected Machines Node of the BDIH. A network of assets and experts with the purpose of placing the knowledge, solutions and tools for digital grinding at the feet of Basque industrial SMEs, to help them achieve optimum part finishes, implement stable, optimised and defect-free processes or avoid critical quality problems in ground parts, such as burns and surface marks, etc.

Grinding is a particularly critical manufacturing process in the finishing of a component; additional to its own technological complexity, it among the final stages of production making it a critical process. Applied in the final stage of the manufacturing process, grinding improves the dimensional tolerance and surface finish of the product, ensuring the final quality of the manufactured part. It is associated with high-performance and high added-value products and, as such, grinding machines and related solutions hold a special added value in the manufacturing environment, providing competitiveness and a level prestige.

The BDIH node delivers services for improving existing processes along the following lines; horizontal and vertical cylindrical grinding, flat grinding and centreless grinding. This is supported by the capacity to provide tests under specific production conditions for parts, a test bench for carrying out experiments and trials, research into superabrasive machining or ensuring surface integrity, among others.

Grinding is able to provide crucial characteristics for manufacturing companies, working with demanding requirements of quality, integrity, reliability and productivity, for which a combination of knowledge of different technologies is required, working in integrated solutions. A grinding solution requires a knowledge of the behaviour of machines and components, materials and their interactions, thermal and dynamic events, and the fundamentals of the diamond and grinding processes, among others.

The Intelligent and Connected Machines node of the BDIH, currently specialised in the digital grinding process, brings it all together with its assets, including grinding machines, sensors, software providing personal and tailored solutions for those machining companies (grinding) and manufacturers of industrial parts and components in high-value sectors such as biomedical, automotive, power generation, railways, aeronautics, cutting tools, capital goods or precision components, among others.

The node benefits from 11 sets of tools and equipment distributed across 6 organisations that make up this network of assets and people serving the whole of the Basque territory.

Coordinated by IDEKO and with the participation of IK4 TEKNIKER, UPV/EHU, Mondragón University, IMH and CEIT. With an investment of more than €6mn in equipment, the node constitutes a collaborative space focused on the experimentation, demonstration and validation of research projects aimed at industrial digitalisation and grinding technology, as well as offering training services to new professional profiles in digital industry, reaffirming the commitment of both the members of the BDIH and the Basque industrial ecosystem to new digital and sustainable technologies, and their effort to be at the forefront of this field.

If you are interested in finding out more about the added value that the node of Intelligent and Connected Machines can bring to Basque SMEs, follow this series of articles where we will tell you in detail about their capacities, assets and services, with a focus on being practical and personalised.

Get in touch with the BDIH to find out how we can bring your company closer to the solutions that interest you most.

Related news

SMARTPM and SubAero Precision Machining announce strategic partnership in India

The collaboration between SMARTPM and SubAero Precision Machining (Group Designcell) is a big step in our global growth, helping us establish a strong foundation in one of the world's fastest-growing industrial markets

Companies with greater gender equality perform better in terms of innovation and are more competitive

The study of the SPRI initiative "Women in Industry" shows that gender equality has an impact on the improvement of company results.

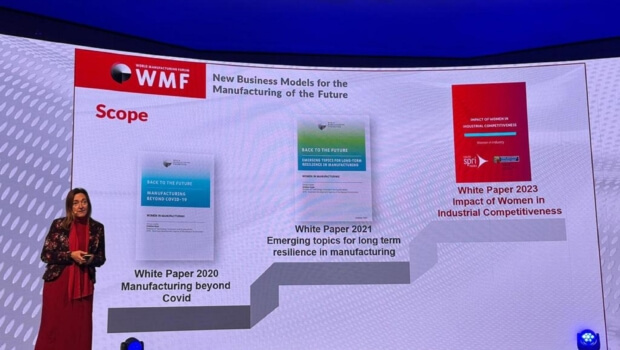

SPRI presents the results of the study on the impact of women on industrial competitiveness at the World Manufacturing Forum

The reports is the continuation of the work carried out by the SPRI Group and the Foreign Network office in Milan since 2020 as leader of the Women in Manufacturing expert group.

Europako fabrikazio-ikerketaren etorkizuna

Donostian, egunotan, MANUFUTURE Conference 2023 egiten ari da, hau da, fabrikazio-industriaren etorkizunari buruzko Europako konferentzia.

Basque Open Industry will show Europe its industrial and technological ecosystem at the European SME Week (SME Week) from 13 to 17 November.

Talent, internationalisation, energy-environmental and technology-digital transitions. SME Week 2023. Exhibition and stands at the BEC: “Rebuild Ukraine”.

Get to know the assets of the BDIH: 5-axis multi-process milling cell, capable of very high speed operations

The University of the Basque Country offers Basque companies, via the BDIH, the possibility to have at their disposal a 5-axis multi-process milling cell, capable of very high-speed operations.

Get to know the assets of the BDIH: Inspection/measurement robotic cell using non-destructive techniques

Tekniker gives the opportunity to Basque companies, by means of the BDIH, of having at their disposal a cell which permits to carry out analysis for the quality control and the non-destructive inspection of pieces.

Get to know the assets of the BDIH: Equipment/Techniques/Methodologies for the study and evaluation of corrosion

Cidetec offers Basque companies, through the BDIH, the possibility of testing their materials with in the order to know their corrosive capacity. For this purpose, the asset uses accelerated and cupro-acetic corrosión climatic chambers, as well as electrochemical and localized techniques for the corrosion studies.

Get to know the assets of the BDIH: Systems for mechanical properties and microstructure determination by magnetic non-destructive measurements

CEIT offers companies, through the BDIH, the possibility of access to quality control systems to detect failures or inspect subsurface processes in a non-destructive manner, allowing costs to be reduced and avoiding wasting parts that could be sold

The Enterprise Europe Network offers Basque companies advice on technological development and the international commercialization of innovative products and services

The Enterprise Europe Network (EEN) has established itself as the perfect public sector tool to complement the efforts of Basque companies in internationalizing their R&D&i and their business in general. Through its advisory and assistance service in the transfer of knowledge, technology and innovation, more and more SMEs are seeing...