Intelligent and connected machines: improve the surface integrity and reliability of your manufacturing processes

In the grinding process, the temperature reached by the workpiece is a decisive factor, since most of the energy required is converted into heat, and the consequences of thermal damage include phase changes and residual stresses. Hence the importance of knowing the heat distribution along the cutting process, in order to be able to accurately predict local thermal damage and thus be able to establish boundary conditions to avoid it. In this process, the appropriate use of coolants and lubricants plays a key role in achieving favourable cooling and lubrication, while generating efficient material removal and effective protection against corrosion. Nowadays, in addition to the cost of these materials (coolants and lubricants), other factors such as fluid disposal, safety measures or recycling, must also be taken into consideration, being nowadays mandatory the use of filtering equipment, which is often expensive and takes up considerable space in the plant.

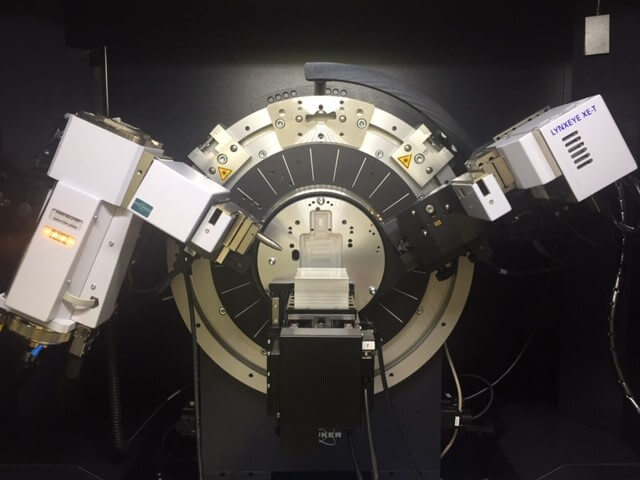

In order to contribute to the improvement of this process, CEIT has an X-Ray Diffractometer for the measurement of crystallographic textures and residual stresses, the latter being one of the main consequences of thermal damage, as mentioned above. This equipment is used both for the identification and quantification of phases and for the measurement of residual stresses of crystallographic textures and phase analysis in thin films by means of a flush angle in many types of materials (metals, ceramics) and thin films. In CEIT, it has been used in most of the projects of the Materials and Manufacturing Division, as well as in the Monitoring Group of the Transport and Energy Division, allowing them: to measure the amount of austenite retained in hardened steels, to identify the crystallographic phases present in a material and their quantification from the intensity of the peaks, both in bulk materials and in thin films, to measure the surface residual stresses and to measure the distribution of crystalline orientations of materials and thin films.

In turn, the UPV/EHU has a research cell for data analysis 4.0 for grinding, which allows massive data collection and efficiency analysis of grinding applications, including new generation grinding wheels, new lubrication and cooling strategies, etc. This is possible thanks to the total sensorisation of a high-performance planer grinding machine and a high-speed cylindrical grinding machine, as well as the integration of a numerical calculation software for the study and simulation of contact conditions. The main services offered by this asset are: testing and analysis of grinding results using new application-oriented grinding wheel formulations, analysis of results in efficient and ecological lubrication systems for grinding, training and proposals for improving apps through data analysis (Machine Learning, Deep Learning), and feasibility studies, among others.

Ensuring component integrity is a critical aspect of grinding. In this sense, TEKNIKER, offers Basque industrial SMEs its Geometric and Material Characterisation Laboratory, which will provide crucial information for determining the optimum process parameters that guarantee the integrity of the components. Thus, this laboratory allows microstructural modification by means of metallographic characterisation, compositional characterisation at the surface, depth and interior, characterisation of crystallographic phases and characterisation of residual stresses. Among the services offered by the asset are: microstructural characterisation of components, compensation of volumetric errors, component life tests, geometric verification of ground parts and training of specialists in this regard.

In addition, the previously mentioned CEIT, also has a System for determining mechanical properties and microstructure by means of non-destructive measurements of magnetic properties. This consists of a non-destructive test-based control system, useful to obtain information of the microstructure and the mechanical properties of the steels or to detect the defects in production, as they can be the variations of superficial hardness, the burns caused by rectification, the residual tensions or the hardened layer, through measures of magnetic emission such as the one of Barkhausen (EMB).

It should be also noted that this system can be used to carry out both manual or automatic measurements by using a robot thanks to various couplings developed.

These solutions show how the BDIH’s Intelligent and Connected Machines node allows Basque companies to incorporate new models, concepts and techniques in the way they produce their parts and products with the aim of providing added value in a particularly critical process such as digital grinding.

Get in touch with the BDIH to find out how we can bring your company closer to the solutions that interest you most.

Related news

SMARTPM and SubAero Precision Machining announce strategic partnership in India

The collaboration between SMARTPM and SubAero Precision Machining (Group Designcell) is a big step in our global growth, helping us establish a strong foundation in one of the world's fastest-growing industrial markets

Companies with greater gender equality perform better in terms of innovation and are more competitive

The study of the SPRI initiative "Women in Industry" shows that gender equality has an impact on the improvement of company results.

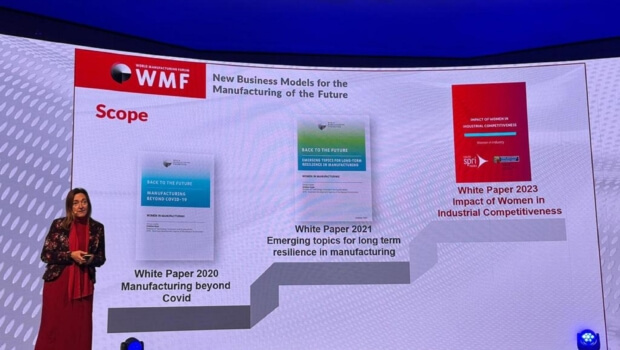

SPRI presents the results of the study on the impact of women on industrial competitiveness at the World Manufacturing Forum

The reports is the continuation of the work carried out by the SPRI Group and the Foreign Network office in Milan since 2020 as leader of the Women in Manufacturing expert group.

Europako fabrikazio-ikerketaren etorkizuna

Donostian, egunotan, MANUFUTURE Conference 2023 egiten ari da, hau da, fabrikazio-industriaren etorkizunari buruzko Europako konferentzia.

Basque Open Industry will show Europe its industrial and technological ecosystem at the European SME Week (SME Week) from 13 to 17 November.

Talent, internationalisation, energy-environmental and technology-digital transitions. SME Week 2023. Exhibition and stands at the BEC: “Rebuild Ukraine”.

Get to know the assets of the BDIH: 5-axis multi-process milling cell, capable of very high speed operations

The University of the Basque Country offers Basque companies, via the BDIH, the possibility to have at their disposal a 5-axis multi-process milling cell, capable of very high-speed operations.

Get to know the assets of the BDIH: Inspection/measurement robotic cell using non-destructive techniques

Tekniker gives the opportunity to Basque companies, by means of the BDIH, of having at their disposal a cell which permits to carry out analysis for the quality control and the non-destructive inspection of pieces.

Get to know the assets of the BDIH: Equipment/Techniques/Methodologies for the study and evaluation of corrosion

Cidetec offers Basque companies, through the BDIH, the possibility of testing their materials with in the order to know their corrosive capacity. For this purpose, the asset uses accelerated and cupro-acetic corrosión climatic chambers, as well as electrochemical and localized techniques for the corrosion studies.

Get to know the assets of the BDIH: Systems for mechanical properties and microstructure determination by magnetic non-destructive measurements

CEIT offers companies, through the BDIH, the possibility of access to quality control systems to detect failures or inspect subsurface processes in a non-destructive manner, allowing costs to be reduced and avoiding wasting parts that could be sold

The Enterprise Europe Network offers Basque companies advice on technological development and the international commercialization of innovative products and services

The Enterprise Europe Network (EEN) has established itself as the perfect public sector tool to complement the efforts of Basque companies in internationalizing their R&D&i and their business in general. Through its advisory and assistance service in the transfer of knowledge, technology and innovation, more and more SMEs are seeing...