Automotive Smart Factory – Competence centre specialised in advanced manufacturing, oriented to the development and implementation of 4.0 manufacturing strategies and to the training of new profiles demanded by the industry

Automotive Intelligence Centre (AIC) is a European value generation centre for the automotive sector operating an open innovation model. Located in Boroa (Biscay), it currently consists of 30 organisations with more than 950 professionals using its facilities. Given the Centre’s goals and activities, it was essential for the AIC to...

Automated intralogistics, guaranteed availability

Ulma Handling Systems is a large company that offers intralogistics solutions to multiple sectors and is located in Oñati (Guipuzkoa). The company identified two principal needs in logistics and supply chain management; firstly, the need to provide their customers with an automated intralogistics facility to guarantee the highest availability rates...

Optimisation and monitoring of the machining-process variables

Aernnova es una empresa líder en el diseño y fabricación de aeroestructuras para los principales OEMs y cuya sede central se encuentra ubicada en Miñano (Álava). Esta empresa detectó varias necesidades en el área de eficiencia productiva, tales como: Disponer de herramientas de diseño avanzado que integren la coordinación de...

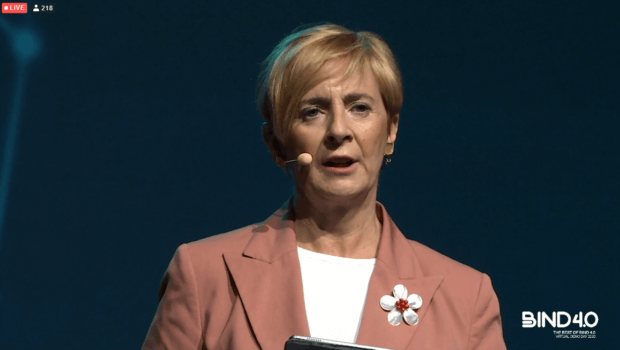

Registration period to participate as a trailblazing company in the open innovation programme BIND 4.0 is now open

The smart industry open innovation platform, BIND 4.0, opens its 6th call for the participation of trailblazing companies interested in leading their market thanks to the incorporation of disruptive technologies and solutions from startups around the world. The registration period will remain open from today until 16 April. This...

4.0 Intelligent and connected machines: Soluciones integradoras para el rectificado digital

After 3 articles in which we have brought together the benefits and added value that its assets and services can offer Basque SMEs in the field of digital finishing, we put an end to the month of Intelligent and Connected Machines node with this article, which includes the opinion of...

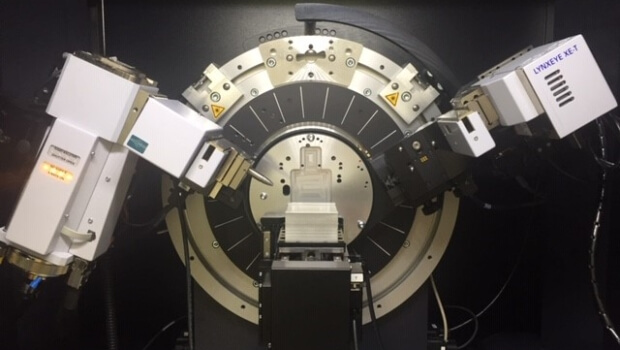

Intelligent and connected machines: improve the surface integrity and reliability of your manufacturing processes

In the grinding process, the temperature reached by the workpiece is a decisive factor, since most of the energy required is converted into heat, and the consequences of thermal damage include phase changes and residual stresses. Hence the importance of knowing the heat distribution along the cutting process, in order...

Meet the 72 Industry 4.0 Startups most valued by the BIND 4.0 Partner Companies and the Finalists for the 5th Edition of the Program

20 de las seleccionadas proceden de Euskadi, 20 son estatales y 32 internacionales

Intelligent and connected machines: Defectology and surface-finishing

Defectology and surface finishing, are two of the most important aspects in the area of grinding. Some types of surface defects that generate rejection in machined parts are “lead error” and “waviness” resulting in a loss of precision in the manufactured parts, which is critical for companies in sectors such...

Intelligent and connected machines: Achieving value-add through improved Digital Finishing

Grupo SPRI presents the node of Intelligent and Connected Machines Node of the BDIH. A network of assets and experts with the purpose of placing the knowledge, solutions and tools for digital grinding at the feet of Basque industrial SMEs, to help them achieve optimum part finishes, implement stable, optimised...

Additive Manufacturing: A Relevant Enabler within Industry 4.0

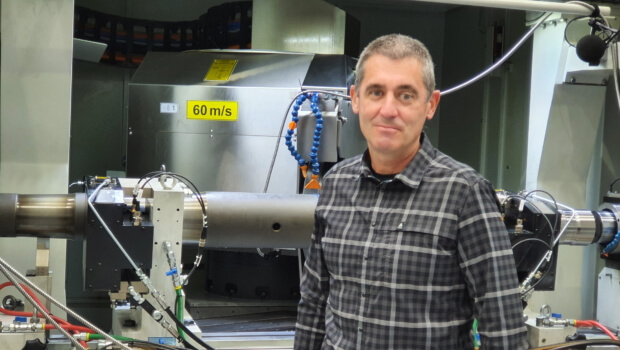

In the photo, we present César Pérez, Technology Director of Lortek. This month dedicated to presenting the technological and human capacities of the Basque Digital Innovation Hub’s Additive Manufacturing node to the Basque industrial companies, closes with The Opinion of the Coordinator of the BDIH’s Additive Manufacturing Node, César Pérez....

ADDIMAT, an ideal partner for the BDIH

In the articles published to date, the SPRI Group, together with the BDIH, has presented the different nodes that make up the group, explaining their areas of action and highlighting the benefits that these can bring to the Basque industry through the implementation and use of 4.0 technologies. This article...

Aditive Manufacturing 4.0: FDM Technique

The techniques described in previous articles have focused on the development of additive manufacturing using metals and technologically complex techniques to obtain parts with difficult geometries. This time we will see that these advanced techniques can also be applied to another specific material: polymers. The processes are relatively analogous, while...

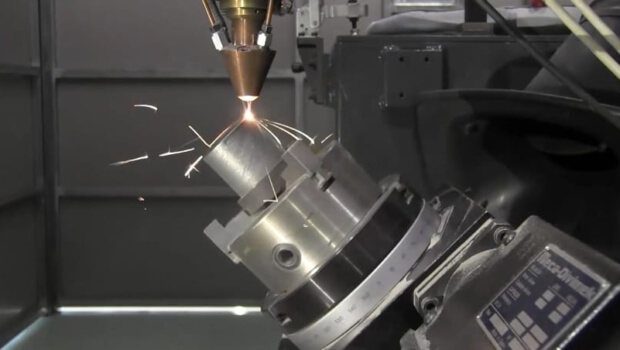

Additive Manufacturing 4.0: Laser Cladding

After highlighting two of the three main technologies in additive metal manufacturing, the time has come to present the latest technique: Laser Cladding. Laser Cladding consists of melting, directly, metallic powder, having previously projected it onto the surface of a base or substrate. Depending on its final use, or, saying...

Additive Manufacturing 4.0: Metal Fusion

Within the industrial landscape, the adoption of Additive Manufacturing is providing companies with innovative, customised and technologically advanced solutions to meet the shifting demands of their customers. By creating metallic objects by adding the material layer by layer, instead of using the techniques of casting, moulding, cutting and other traditional...

The Closing word on…Advanced materials

Ibon Ocaña, European Business Development at CEIT. This month on advanced materials closes with some words from the coordinator of the Advanced Materials node of the BDIH, Ibon Ocaña. Ibon Ocaña holds a PhD in Engineering from the University of Navarra, and has an extensive and applied research career in...

Materials 4.0: make your forging processes sustainable and energy efficient

In this article Grupo SPRI, together with the BDIH and its Advanced Materials Node, continues develop our knowledge and capacity to innovate metal manufacturing processes through forging technology, and in particular to the techniques and solutions that make them increasingly sustainable. In the previous article, we detailed how to use...

Materials 4.0: Combine new and different materials to meet the challenge of manufacturing parts

In this article, SPRI Group, together with the BDIH and its Advanced Materials Node, shows manufacturing companies how to address the challenges of using different materials in the same part or structure and increase their product value, adapting both the processes of joining materials and the company’s own manufacturing...

Materials 4.0: Three state-of-the-art surface modification techniques for your industrial components

This article details 3 techniques for modifying leading surfaces, which make it possible to significantly improve the characteristics of manufactured parts in aspects such as resistance to external agents (oxidation, corrosion, etc.), optimisation of friction and durability, and resistance to wear and tear, among others.

Materials 4.0: producing better performing, more durable and more sustainable products in the Basque Country!

The SPRI Group, together with the BDIH, makes the Advanced Materials Node available to Basque SMEs. The Node is a network of assets and experts working to show the opportunities for companies and demonstrating the value that advanced materials can provide to the Basque industry, especially in the automotive, metal...

4.0 solutions: robotics for quality control

In this article from our “solutions 4.0” series we present the robots that provide the solution to specific needs in quality control of parts; from dimensional and surface control of produced parts using 2D/3D vision to integrity and defect control through 3D vision technologies, ultrasound and thermography. These technologies make...