The Closing word on…Advanced materials

Ibon Ocaña, European Business Development at CEIT.

This month on advanced materials closes with some words from the coordinator of the Advanced Materials node of the BDIH, Ibon Ocaña.

Ibon Ocaña holds a PhD in Engineering from the University of Navarra, and has an extensive and applied research career in the field of advanced materials which he has developed from the CEIT technology centre. He has been teaching at Tecnun, University of Navarra, for more than 25 years, and was a visiting scientist at Intel Labs in Oregon, US, for two years. His main field of work relates to the mechanical properties of materials at the macro and micro level (especially mechanical reliability and fracture mechanics), and today, among other things, he coordinates the Advanced Materials node of the BDIH.

In this article, Ibon shares his knowledge on the technology, assets and talent of the node, as well as international trends in advanced materials and on how the node works to strengthen the competitiveness of the Basque industry.

The Advanced Materials node of the BDIH has more than 65 assets, distributed among 15 organizations (AZTERLAN, CEIT, CIC ENERGIGUNE, CIC NANOGUNE, CIDETEC, GAIKER, IDEKO, IKERLAN, LORTEK, MONDRAGON UNIBERTSITATEA, POLYMAT,TECNALIA, TEKNIKER, TKNIKA, UPV/EHU) as well as a considerable number of experts who, together, provide advice and support to Basque industry on the scaling up of new functionalities and processes associated with the incorporation of advanced materials by Basque industry.

The members of the node have worked in recent years with around 100 Basque companies, exploring how to incorporate a series of technologies into the value chain of these sectors for the production of advanced materials and coatings with the goal of achieving products which have a better performance, are more durable and more sustainable.

These companies are seeking to improve the performance of current materials in the face of increasingly demanding market applications, the use of new materials, more reliable and versatile methods of joining materials adapted to new design and manufacturing strategies, new more efficient and durable coatings, lowering product costs, and services that help to extend the useful life of materials and determine their recyclability.

Based on these common requirements, the node benefits from top-end assets available to support companies in responding to individual client demands and specifications.

In terms of the design and development of materials, the node makes it possible to address both the evolution of materials that companies are already using (for example, by developing new qualities of steel) and the challenge inherent in replacing metal parts in assembly with others made from composite materials while adopting automated solutions for processing composites on assembly lines.

“These technologies allow companies to increase the added value and competitiveness of their products in the global market” according to Ocaña.

As for the manufacturing processes, novel advanced forming processes allow the obtainment of parts with better metallurgical and mechanical characteristics, he continues, these processes in turn allow the companies, currently undergoing a transformation, to adapt their processes to more efficient technologies, both energetically and economically, and with respect to the raw materials; “[…] specifically the metal forming sector, with a long tradition in the Basque Country, benefits from these developments that allow it to give service in an agile and competitive way in sectors as complex as the automotive, aeronautical or energy sectors”.

The coating and surface solutions offered by the node improve the characteristics of the manufactured parts in aspects such as resistance to external agents (oxidation, corrosion, etc.), optimisation of lubrication and durability and wear resistance among others. These are very popular and demanded services “that allow companies to offer high durability products, improving functionality and/or aesthetics, complying with environmental regulations”.

As far as advanced joints are concerned, the main challenges for companies come, on the one hand, from the introduction into the manufacturing processes of different materials, “with the need to design reliable and durable joints, for example, between metallic and composite materials” and, on the other hand, from the need to vary their joining processes for technological (higher design requirements) or environmental reasons. Companies in the automotive and aeronautical sectors are those that have benefited most from the services offered by the node agents, as their coordinator explains.

Services related to materials and processes in the circular economy support the industrial network with ecological designs and component life cycle analysis, and provide services that help to extend the useful life of materials and determine their recyclability. According to the coordinator, the demand for such circular economy services to improve the sustainability of Basque industry has increased considerably in the last decade, “We have seen a practical interest by companies in replacing or reducing their dependence on some of the strategic materials they were using and in understanding the economic impact of responsible environmental management of the entire life cycle”.

The Advanced Materials node of the BDIH is especially active in RD&I activities at an international level, participating in initiatives that mark the national and international technological vanguard such as EUMAT, ESTEP, MATERPLAT, among others, and working hand in hand with reference organisations such as the Fraunhofer Institutes, VTT, RISE, TNO, among many others, and international companies such as Arcelor, Intel, Airbus or Volkgswagen as well as with the entire national and European ecosystem.

“We often act as a bridge between the Basque industrial fabric and the international one, helping in the internationalisation of our companies, providing specific support to the development of products and applications in advanced materials to SMEs and startups”,

“From the Advanced Materials node we offer the Basque industry a network for practical development, experimentation and testing with innovative technologies” concludes Ocaña, “and we invite you to come and explore it”.

Contact the BDIH to find out how we can bring your company closer to the solutions that matter most to you.

Related news

SMARTPM and SubAero Precision Machining announce strategic partnership in India

The collaboration between SMARTPM and SubAero Precision Machining (Group Designcell) is a big step in our global growth, helping us establish a strong foundation in one of the world's fastest-growing industrial markets

Companies with greater gender equality perform better in terms of innovation and are more competitive

The study of the SPRI initiative "Women in Industry" shows that gender equality has an impact on the improvement of company results.

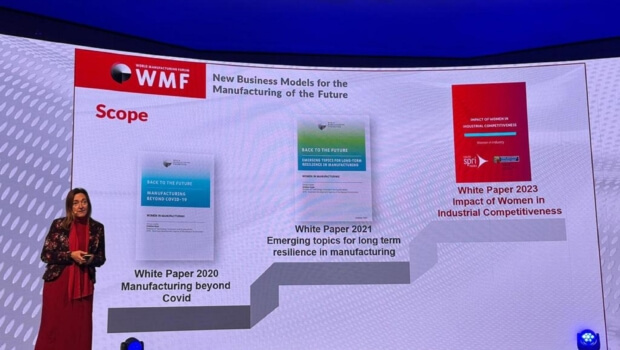

SPRI presents the results of the study on the impact of women on industrial competitiveness at the World Manufacturing Forum

The reports is the continuation of the work carried out by the SPRI Group and the Foreign Network office in Milan since 2020 as leader of the Women in Manufacturing expert group.

Europako fabrikazio-ikerketaren etorkizuna

Donostian, egunotan, MANUFUTURE Conference 2023 egiten ari da, hau da, fabrikazio-industriaren etorkizunari buruzko Europako konferentzia.

Basque Open Industry will show Europe its industrial and technological ecosystem at the European SME Week (SME Week) from 13 to 17 November.

Talent, internationalisation, energy-environmental and technology-digital transitions. SME Week 2023. Exhibition and stands at the BEC: “Rebuild Ukraine”.