Materials 4.0: the BDIH and the circular economy

Innovation in Materials has historically provided the Basque industry with significant advances in the development of new products and in the improvement of existing production processes. Currently, and over the next few years, innovation in Advanced Materials will be the core around which the incorporation of new functionalities and the improvement of their properties will revolve, providing greater added value to the products and processes of Basque SMEs, without losing sight on sustainability.

Sustainability is interrelated with the circular economy, an economic concept where the value of products, materials and resources (water, energy…) are maintained in the economy for as long as possible, and where the generation of waste is reduced to a minimum. The aim is to implement a new economy, circular and non-linear, based on the principle of “closing the life cycle” of products, services, waste, materials, water and energy. At present, the circular economy in the Basque Country represents 1.12% of the GDP, with an annual gross income of €764m, according to the report “Diagnosis of the Circular Economy in the Basque Country Industry“.

According to this report, if more innovative circular solutions were implemented, it is estimated that there would be an average potential saving of 6% in the consumption of raw materials, which would mean savings of €2bn for Basque industry. The metal (steel, casting, metal products) and mobility (automotive, aeronautics) sectors would accumulate half of the potential savings of Basque industry.

This article is dedicated to those Basque SMEs interested in reducing the consumption of raw materials and finding alternatives and promoting their recycling and reuse.

The SPRI Group, together with the BDIH, combines in its Advanced Materials Node capabilities that offer services focused precisely on the sustainability needs of SMEs. These services support the industrial fabric in eco-design tasks and life cycle analysis of components, to respond to the challenges of sustainable development, and help to extend the life of materials and determine their recyclability.

For example, TEKNIKER is developing materials with several added functionalities, which could be candidates for adaptation and application in the generation of anti-viral surfaces, to help and protect in the fight against the COVID-19 disease. These new functionalities do not modify the life cycle of the final product and in some cases they even extend it. These materials are developed, among others, from its active Laser surface texturisation of industrial components with 3D geometry, allowing the manufacture of industrial components with 3D surfaces characterized by a texture at the micro and submicrometric scale that gives the component an antimicrobial character against different bacteria.

CEIT, on the other hand, opens the possibility of producing complex components by optimizing the use of material, combining several apparatus and tools in its Near Net Shape Pilot Plant, where large, medium and small components can be produced using the most appropriate techniques. This asset also offers the possibility of adjusting performance by means of heat treatments and specially designed powder coatings.

GAIKER, from its Plastic and Composite Materials Manufacturing Unit, offers services for the circular economy of development and implementation of post-process recycling systems for plastic and composite parts and waste, development of products based on recycled carbon, analysis of the recyclability of product materials in all their phases, eco-design focused on optimising the circularity of materials, and evaluation of the sustainability of materials, processes and products from the perspective of life cycle analysis. These services have been put into practice with companies in the context of various R&D projects in different industrial sectors.

TECNALIA has got various assets related to the circular economy, although the Pilot Plant for the recovery of resources, the replacement of critical materials and the circular economy should be highlighted. These facilities (laboratory and pilot plants) for the development of recovery processes, based on hydrometallurgical, pyrometallurgical and ionic-metallurgical technologies and their combinations, make it possible to offer a solution to waste management problems. These actions are focused on the recovery of the high-value elements present in the wastes and which can be used as substitutes for conventional raw materials (metals of high economic value or critical metals, for example), or on the reuse of uncontaminated wastes after impurity removal treatment. This asset also includes installations specifically designed for the metallurgical industry for developments related to energy and resource efficiency and towards concepts of circular economy, such as new furnaces, new heating systems, new processes for the recovery of metals from waste, minerals or slag and processes for the recovery of energy from industrial waste.

The complete list of the assets of the advanced materials node that support these services can be accessed from the BDIH catalogue, can be visited, and can be tested with the technical teams to assess against the individual needs of each company, with the security of working with experts and state-of-the-art equipment.

The solutions presented in this article are an example of how the Advanced Materials Node of the BDIH helps companies to adapt their processes to technologies of greater added value, and more efficient both energetically and economically and in terms of the materials used.

If you are interested in deepening your knowledge of what the Advanced Materials Node of the BDIH offers, follow this series of articles on Materials 4.0 where we tell you in detail which are the capacities, assets and services of the node in a practical, applied way.

And contact the BDIH to find out how we can bring your company closer to the solutions that interest you most.

[1]https://www.euskadi.eus/contenidos/documentacion/economia_circular/es_def/adjuntos/EstrategiaEconomiaCircular2030.pdf

Related news

CIC biomaGUNE launches a company that will transform disease diagnosis by using nanosensors

Taldeki Biosolutions will be developing sensors for rapid, cost-effective, robust antibody detection, thus overcoming the stability and cost problems of current in vitro diagnostics

SVE stands out for the gender equality in its top management

The company, based in the Álava Technology Park, is one of the participants in a project to pinpoint best practices in gender equality led by the SPRI Group

Engranajes Juaristi stands out for the gender equality in its top management

The company in Zarautz is one of the participants in a project to pinpoint best practices in gender equality led by the SPRI Group

VIVEbiotech Secures Growth Investment from Ampersand Capital Partners to Expand Lentiviral Vector Development and Manufacturing Capabilities

Support the execution of a robust pipeline of customer projects for innovators developing groundbreaking in vivo and ex vivo cell and gene therapies.

SMARTPM and SubAero Precision Machining announce strategic partnership in India

The collaboration between SMARTPM and SubAero Precision Machining (Group Designcell) is a big step in our global growth, helping us establish a strong foundation in one of the world's fastest-growing industrial markets

CIC nanoGUNE launches a new call: Industry Collaborative Research Positions

Programa honen helburua da ikertzaile profesionalak tokiko erakundeetan sar daitezen erraztea

Basque Trade & Investment supports Basque companies in international renewable energy congresses

International experts have presented the opportunities offered by the U.S. and French markets to Basque companies in two specialized congresses in the field of marine energy.

Companies with greater gender equality perform better in terms of innovation and are more competitive

The study of the SPRI initiative "Women in Industry" shows that gender equality has an impact on the improvement of company results.

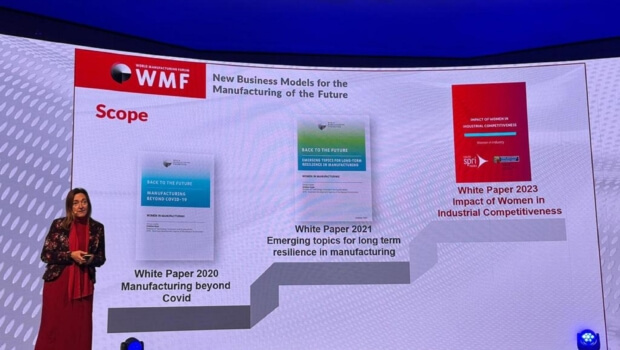

SPRI presents the results of the study on the impact of women on industrial competitiveness at the World Manufacturing Forum

The reports is the continuation of the work carried out by the SPRI Group and the Foreign Network office in Milan since 2020 as leader of the Women in Manufacturing expert group.

Europako fabrikazio-ikerketaren etorkizuna

Donostian, egunotan, MANUFUTURE Conference 2023 egiten ari da, hau da, fabrikazio-industriaren etorkizunari buruzko Europako konferentzia.