The Closing Word on… Robotics

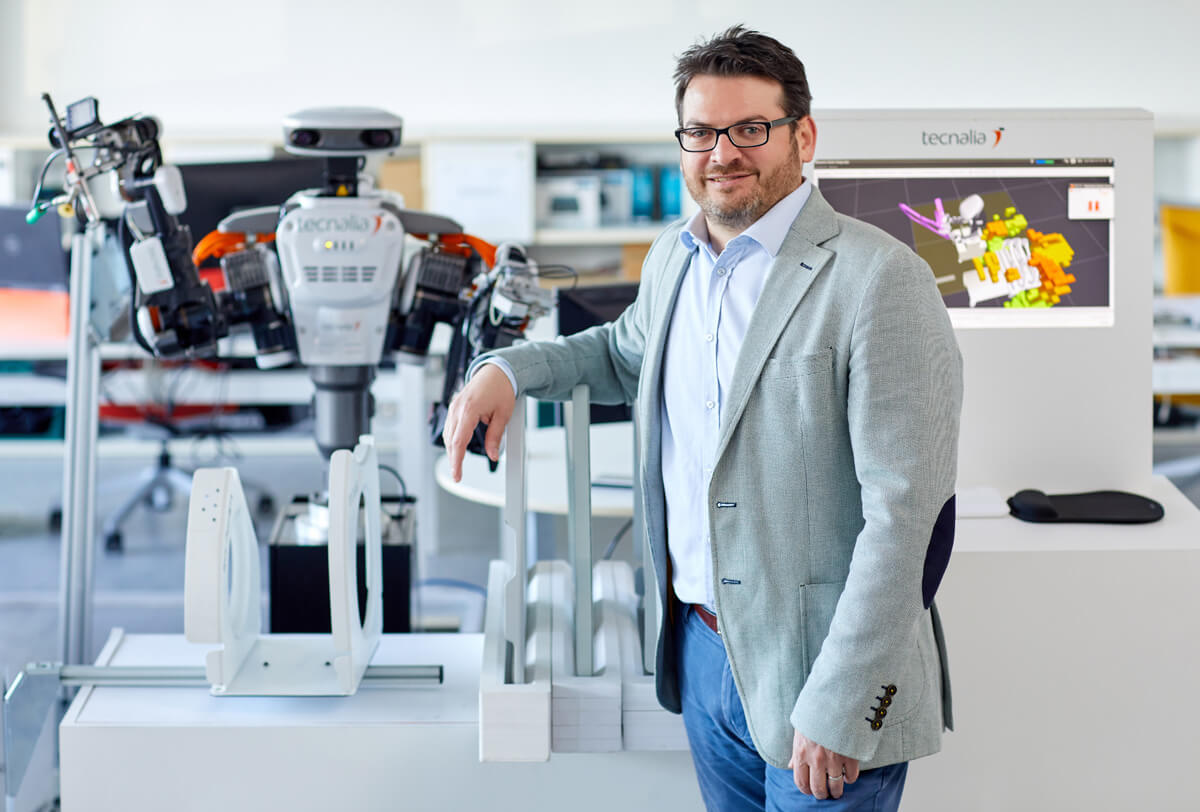

Damien Sallé, Cross-departmental Coordinator of Robotic Technology at Tecnalia and Head of Market for Advanced Manufacturing Robotics at TECNALIA.

We close our robotics month with the opinion of our Coordinator of the Flexible and Collaborative Robotics Node, Damien Sallé. Damien will share his knowledge about the technology, assets and talent of the node, about international trends in robotics and about how the node works to strengthen the competitiveness of Basque industry.

Damien is a mechanical engineer, with a doctorate from the prestigious French Institute of Intelligent Systems and Robotics (ISIR) specialised in robotics applied to minimally invasive surgical interventions. From there he worked at Robosoft, a leading robotics and services company, before moving onto Tecnalia to focus on robotics applications for advanced manufacturing.

The Collaborative and Flexible Robotics Node (Robotics Node) of the BDIH has more than 25 sets of equipment, distributed among 9 centres ( (TECNALIA, TEKNIKER, IDEKO,CEIT, VICOMTECH, UPV/EHU, Mondragon Unibertsitatea, Innovalia, LORTEK)). These world-class assets are backed up with a considerable number of experts. Who , together, provide advice to Basque industry on the design, testing, validation and implementation of practical solutions incorporating these types of robotic technologies.

Over the last decade, the members of the ROBOTICS node have enabled over 50 Basque companies to explore robotic solutions to automate production processes and increase flexibility in reducing time for manufacturing.

These companies include manufacturers of finished products both for final consumers and other industrial companies, suppliers of parts and components, and machining companies. Each company shares the common the need to improve productivity, ensure the quality of the final product, and increasing safety through minimising worker exposure.

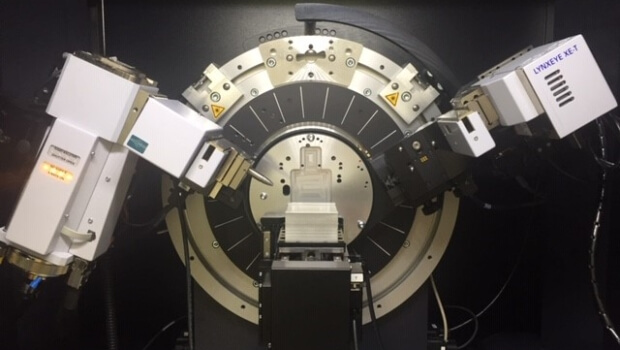

The ROBOTICS Node offers state-of-the-art knowledge and equipment to reach these goals. Working with the Node you can reach zero defects in production in by incorporating robotic technologies for quality control based on the latest technologies in vision (artificial vision, ultrasound, thermography, etc.).

“These technologies facilitate the dimensional control of each part without contact, meaning it is the robot which validates the part,” according to Damien.

The advanced manipulation with flexible and autonomous robots allows the automation of complex tasks where it is currently not profitable. The robots are equipped with vision sensors and computational capacities which enable them to overcome the “high mix, low volume” manufacturing challenge; wide variety of parts with a small volume of each produced.

The technologies have various practical applications: packing; bin picking – taking a piece from a box without commands; kitting – placing pieces into a prepared kit/box; transfer of goods; etc. Depending on the accuracy, speed and robustness required the BDIH has specific teams to evaluate and test the feasibility of the technology.

“We have worked with companies that, for example, manufacture many references of hydraulic distributors for aeronautics, and the feasibility of robotizing these almost unitary assemblies has been demonstrated,” adds Sallé.

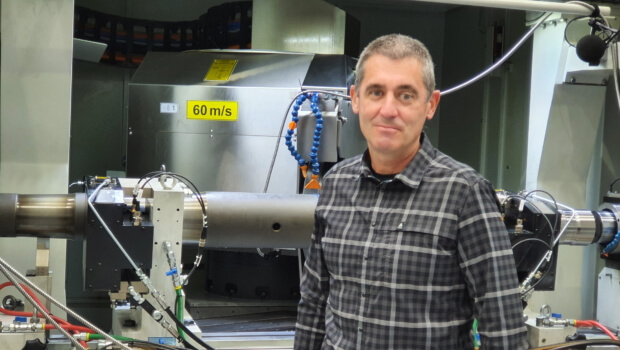

The automation of component manufacturing processes requires, which includes milling, drilling, riveting, polishing and other tasks, auxiliary elements like vision and force sensors to transform the robot from an automaton into a flexible and adaptable system, which allows these tasks to be carried out with the precision and robustness they demand.

“We know from experience that achieving the robotization of these processes requires optimisation of the process-robot binomial, what do I mean by this? For example, the movement of the drilling process impacts on the precision of the robot while vice versa, the rigidity and vibration of the robot impacts on the quality of the drilling,” emphasizes Sallé.

In another testament of the responsiveness of the BDIH Node, technologies such as autonomous navigation enable sophisticated services for internal logistics with mobile robots. With new developments in vision and simulation, we can increase flexibility in production through safer and more collaborative human-robot interaction.

“We can combine mobile platforms with robotic arms so that we can not only transport, but also detect, grab and manipulate all types of components,” says Sallé.

The Robotics Node of the BDIH is especially active in R+D+i activities at an international level, participating in initiatives that establish the international benchmark such as SPARC, Eurobotics, AER-ATP or EFFRA, among others, and working with reference organizations such as the University of Montpellier, the Fraunhofer IPA Institute or the Danish DTI, among many others. The Node also works with international robotics companies such as ABB, Kuka or Comau, as well as with the entire ecosystem of national and European integrators.

“We bring to Basque SMEs, European support programmes such as Robottnet, ESMERA, ROSin and RobotUnion, which provide specific support to product development and robotic applications to SMEs and start-ups,” the coordinator affirms.

“We are experimenting with 3D vision for bin-picking and flexible handling with several companies, technologies that we see with a direct application in Basque industry because of the versatility, reduced programming, and the savings it generates in the incorporation of new reference parts,” says an enthusiastic Damien.

“We offer a network of experimentation and testing with innovative technologies that at the same time are practical, allowing the industry to anticipate problems in their daily lives and develop new products for the Basque industry.” concludes Damien Sallé, “We invite you to explore it to develop specific projects”.

Contact the BDIH to find out how we can bring your company closer to the solutions that matter most to you.