Additive Manufacturing 4.0: experiment and transform the way you conceive, design and manufacture your products

SPRI Group, together with the BDIH, presents the Additive Manufacturing node to Basque SMEs, a network of assets and experts focused on demonstrating to Basque industry the opportunity for incorporating new models, concepts and techniques in the production of existing parts and products.

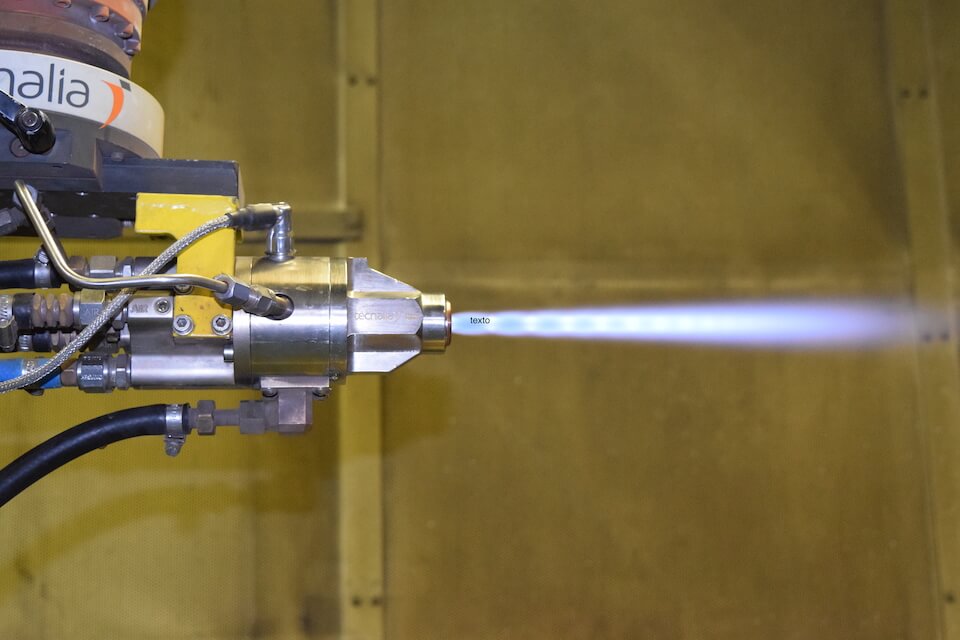

Additive manufacturing refers to manufacturing parts from a 3D model and encompasses a set of technologies which enable the creation of three-dimensional objects by superimposing multiple layers of material. The concept of additive manufacturing consists of creating an object by adding the constituent material, layer by layer, instead of traditional methods such as casting, moulding, cutting and other processes.

The application of additive manufacturing in industry has already been proven and has led to the transformation of the supply chain, the improvement of customisation processes and even led to the radical change of entire sectors.

Compared to other more traditional manufacturing techniques, Additive Manufacturing technology makes it possible to produce parts up to 90% faster. Thanks to the precision use of material in manufacturing, this technique does not produce waste, reducing costs and increasing the sustainability of production.

A wide range of technologies represent this new industrial revolution,. The possibility of dispensing with tools, reproducing any geometry that humans can imagine (and draw), and the immediacy of response to changing consumer demand, makes additive manufacturing a real cornerstone of the Basque industrial future.

The Basque Country holds great capacities in this area, both on an industrial level, where the ADDIMAT Association plays an important role, and on a scientific-technological level, where the Additive Manufacturing node within the framework of the Basque Digital Innovation Hub connects the main agents to jointly offer the best service to SMEs.

The node supports Basque companies to improve the production volumes, add functionalities and new capacities to its processes or products, reduce the material used, manufacture objects with complex geometries at the request of clients and associates, reduce the manufacturing cost for short series, increase the speed and reduce the cost of prototyping, incorporate its products and processes into the circular economy and know in greater detail the behaviour of its products and processes (digitisation).

The easily accessible node has 33 assets distributed among the 13 organizations that make up this network covering the entire territory. It is coordinated by LORTEK and made up of CEIT, CIDETEC, GAIKER, IDEKO, IKERLAN, IMH, INNOVALIA, Mondragon Unibertsitatea, TECNALIA, TEKNIKER, the University of the Basque Country, and VICOMTECH. The node provides a 360º vision of additive manufacturing technologies taking into account the entire value chain, from materials to post-treatments and functionalisation, also collaborating with ADDIMAT, the Spanish Association of Additive and 3D Manufacturing Technologies.

Find out more about the node through this series of articles on Additive Thinking 4.0 where we tell you in detail what are the capabilities, assets and services of it in a practical and close way.

Contact the BDIH to find out how we can bring your company closer to the solutions that interest you most.

Related news

Companies with greater gender equality perform better in terms of innovation and are more competitive

The study of the SPRI initiative "Women in Industry" shows that gender equality has an impact on the improvement of company results.

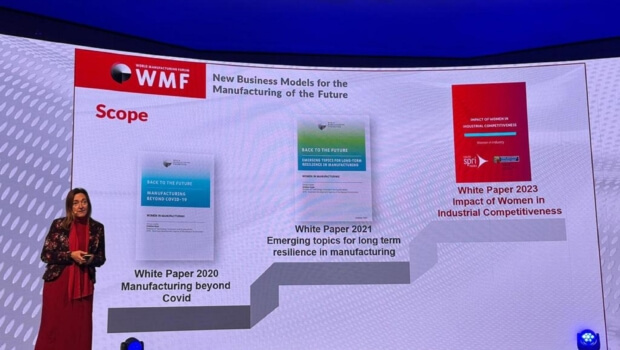

SPRI presents the results of the study on the impact of women on industrial competitiveness at the World Manufacturing Forum

The reports is the continuation of the work carried out by the SPRI Group and the Foreign Network office in Milan since 2020 as leader of the Women in Manufacturing expert group.

Europako fabrikazio-ikerketaren etorkizuna

Donostian, egunotan, MANUFUTURE Conference 2023 egiten ari da, hau da, fabrikazio-industriaren etorkizunari buruzko Europako konferentzia.

Get to know the assets of the BDIH: 5-axis multi-process milling cell, capable of very high speed operations

The University of the Basque Country offers Basque companies, via the BDIH, the possibility to have at their disposal a 5-axis multi-process milling cell, capable of very high-speed operations.

Get to know the assets of the BDIH: Inspection/measurement robotic cell using non-destructive techniques

Tekniker gives the opportunity to Basque companies, by means of the BDIH, of having at their disposal a cell which permits to carry out analysis for the quality control and the non-destructive inspection of pieces.