Get to know the assets of the BDIH: Parts development centre using Binder Jetting technology

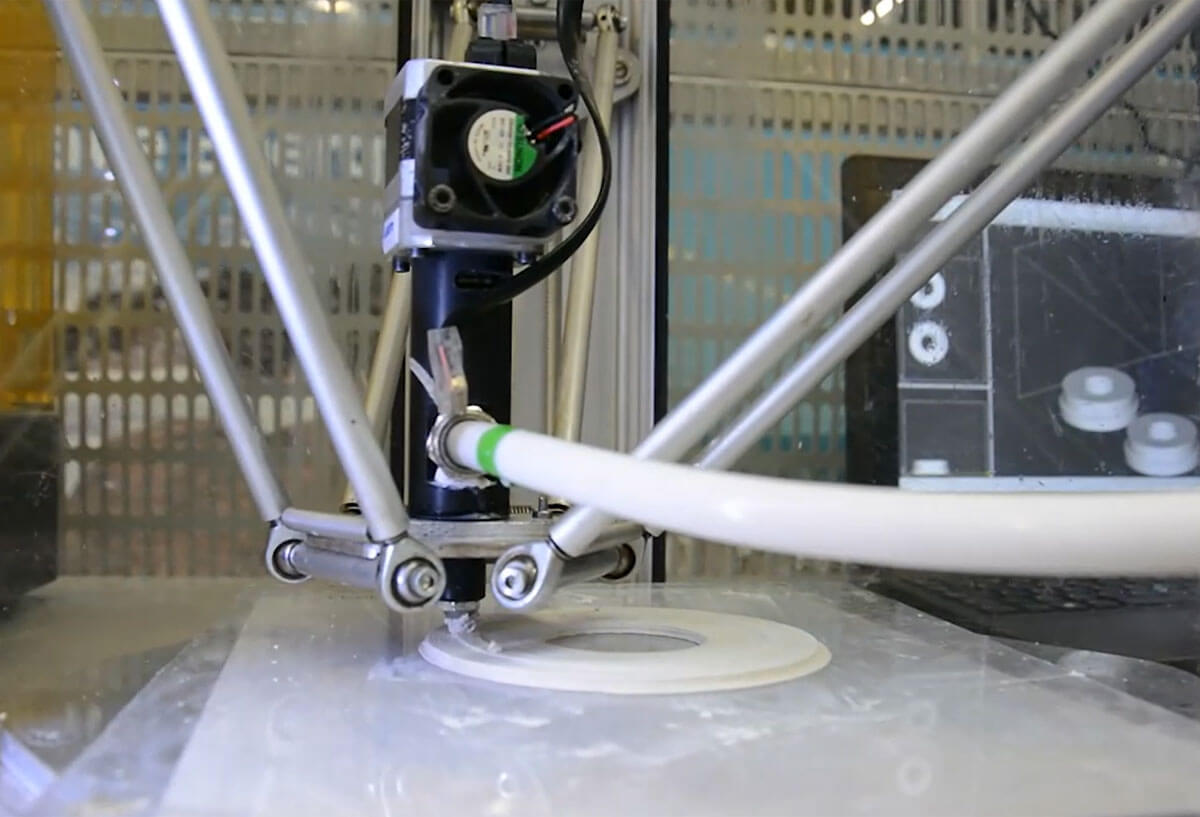

Tecnalia, as an agent belonging to the node of Additive Manufacturing of the BDIH, offers Basque companies the development of powder bed processes for the direct manufacturing of parts with different shapes and large surface coatings made of metallic, ceramic or composite materials.

Through this asset, the companies can carry out all types of services by means of the Binder Jetting technology, from the feasibility studies to the development of components and composite materials; as well as the manufacture of prototypes. As a last service, it is important to highlight its formative character.

Use case

Deguisa has used this asset to research the most appropriate additive manufacturing methods for refractory raw materials.

Deguisa was created in 1966 as a company dedicated to the engineering, design and manufacture of refractory linings and materials along with combustion and control equipment. With a plant in Amurrio since 1974, it has been able to expand its market by being able to directly produce parts with intricate geometries and short production runs using materials that ensure the properties provided by the traditional refractories. For that matter, Tecnalia has helped Deguisa define the technology and materials suitable for the 3D printing of refractory parts, opening the door additional to the manufacture of advanced ceramics.

Do not miss the video of Deguisa, where the manager of Quality, Engineering and Purchases, Nerea Alijarte, explains all the details of this use case and the benefits obtained.

Related news

Get to know the assets of the BDIH: 5-axis multi-process milling cell, capable of very high speed operations

The University of the Basque Country offers Basque companies, via the BDIH, the possibility to have at their disposal a 5-axis multi-process milling cell, capable of very high-speed operations.

Get to know the assets of the BDIH: Inspection/measurement robotic cell using non-destructive techniques

Tekniker gives the opportunity to Basque companies, by means of the BDIH, of having at their disposal a cell which permits to carry out analysis for the quality control and the non-destructive inspection of pieces.

Get to know the assets of the BDIH: Equipment/Techniques/Methodologies for the study and evaluation of corrosion

Cidetec offers Basque companies, through the BDIH, the possibility of testing their materials with in the order to know their corrosive capacity. For this purpose, the asset uses accelerated and cupro-acetic corrosión climatic chambers, as well as electrochemical and localized techniques for the corrosion studies.

Get to know the assets of the BDIH: Systems for mechanical properties and microstructure determination by magnetic non-destructive measurements

CEIT offers companies, through the BDIH, the possibility of access to quality control systems to detect failures or inspect subsurface processes in a non-destructive manner, allowing costs to be reduced and avoiding wasting parts that could be sold

Get to know the assets of the BIDH: PVD pilot line coating facilities for industrial components of Tekniker

Tekniker offers Basque companies, via the BIDH, the possibility of developing by means of PVD technologies coatings for plastic and mechanical components as well as solar collectors with different properties depending on its industrial application.

Get to know the assets of the BDIH: Advanced fabrication and characterization of biomaterials of CIC biomaGUNE

CIC biomaGUNE offers the Basque companies, through the BDIH, the possibility to fabricate and characterise nanostructures applied to molecular imaging, regenerative medicine and biomaterials.

Get to know the assets of the BDIH: Robotic system for flexible manipulation of objects and tools

Tekniker gives the opportunity to Basque business, by means of the BDIH, of having at their disposal a cell which permits to automate operations for the manipulation of pieces, or manipulation of tool on piece.

Get to know the assets of the BDIH: prototyping laboratory

The prototyping laboratory of Tekniker is dedicated to the integral design of health products while complying with the specific standards for medical devices ISO 13485. Through the use of digital tools and rapid prototyping systems, they are able minimize development costs before going on to the experimentation phases having checked...

Get to know the assets of the BDIH: Advanced systems for metallurgical characterization of metals in liquid and solid state in industrial plants

The node of New Materials of the BDIH assists and advises Basque companies in the selection, design and development of materials to meet the current challenges of the industry. AZTERLAN foundation is one of the agents of this node and has equipment and expertise for the metallurgical characterization of metal...

Get to know the assets of the BDIH: Pilot plant for the study of advanced joints of Lortek

Lortek, as an agent belonging to the node of Additive Manufacturing of the BDIH offers Basque companies the opportunity of having available their asset “Pilot plant for the study of advanced joints” in their headquarters of Ordizia (Gipuzkoa). This pilot plant is specially designed for the study of MIG/MAG arc...