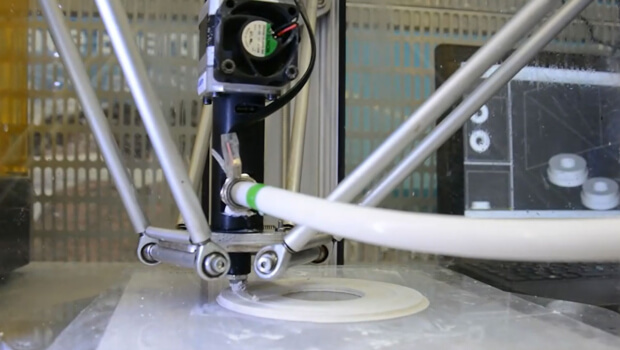

Get to know the assets of the BDIH: Advanced systems for metallurgical characterization of metals in liquid and solid state in industrial plants

AZTERLAN offers companies, through the BDIH, its services for the development and search for new materials to help them reduce costs and be more effective. Basque companies have the possibility of using these services on a first-time basis in the pilot plant of AZTERLAN to carry out their proofs of concept and once tested be moved to their own production plants. In AZTERLAN’s premises, the company can perform molten metal fluid analysis to then analyse the characterization of the metals so as to obtain valuable measures for the subsequent processes of components manufacture.

Among the services of AZTERLAN delivered by means of this asset it is worth mentioning their software systems both for control and simulation which, unlike others, incorporates the metallurgical behaviour of the materials. The use of these systems represents an improvement for the companies both in the level of results, and the speed and quality response.

Finally, it is important to highlight the benchmarking services which help companies to position themselves in the top rank of the markets, supported by the AZTERLAN research team’s in-depth knowledge of metallurgical process transformation.

Use case

Draxton Atxondo is a nodular iron cast foundry which manufactures safety components for the automotive sector. Today, they are the leading supplier of disc brakes in Europe with an annual production of more than 30 million forks, which represents a 45% share of the European market. Draxton was searching for a way to improve the performance of the foundry, this is, the amount of metal sold versus the amount of metal to be melted and additivated.

Through the BDIH Konexio programme, Draxton Atxondo has carried out a proof of concept at the Azterlan’s facilities and developed a material that allowed them to improve their performance ratio in a spectacular way, climbing from 50% to 70%, and lowering the production energy costs considerably.

Discover all the details of this use case: Marta Ratón, plant manager, and Lorenzo Martín, production manager at Draxton will tell you in this video how their performance and competitiveness in the Atxondo plant have improved significantly.