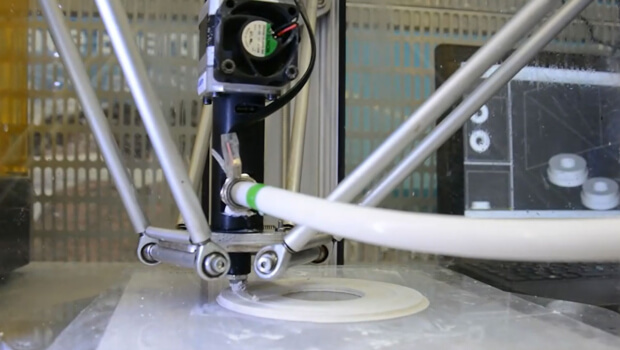

Get to know the assets of the BDIH: Inspection/measurement robotic cell using non-destructive techniques

The cell offers the possibility to assess the viability of the inspection, both in-line and off-line, through the analysis of the requirements related to its resolution, time cycles, and the automation of solutions for quality control and piece handling.

Thanks to this asset, the companies are able to carry out technical viability studies and analyse the limitations associated with the detection of defects or the positioning of specified objects in handling operations.

Likewise, proofs of concept can be carried out to simulate different configurations and working conditions in the piece to quickly find the final inspection and measurement solution.

Tekniker also offers demo services and outreach to collaborative and flexible robotics for the inspection/measurement of component.

As a final service of the asset, it is important to highlight its formative nature: Techniker offers practical training in the application of collaborative and flexible robotics for the inspection/measurement of components.

Use case

Ingenersun has used this asset along with other robotic systems for the flexible assembly of components and tooling to incorporate new technologies such as physical algorithm simulation systems in order to help a customer optimise its production process through the automated loading of its trucks.

Ingenersun is an engineering company dedicated to the automation of industrial processes. Through Tekniker’ asset, it has been able to add new flexible and collaborative robotic technologies at its service and develop a valuable tool for the company, to be used both in manual and automated environments and become a market opportunity for the future.

Do not miss the video of Ingenersun, where its Commercial Director, Sergio Bilbao, and its Manager, Joseba Rodriguez, will tell us all the details of the case.