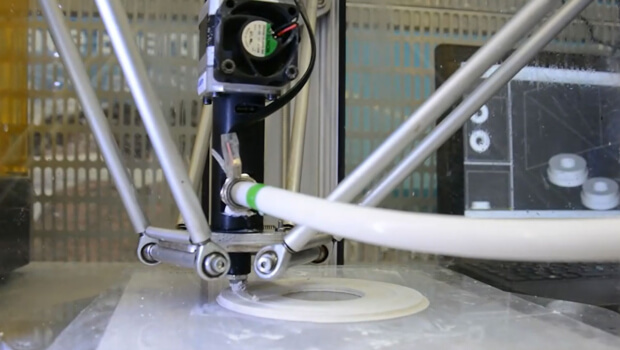

Get to know the assets of the BDIH: Research unit for superabrasive and multitasking machining

UPV/EHU’s Research unit for superabrasive and multitasking machining is one of the assets of BDIH’s Smart and connected machines node. It is a research and development unit for advanced applications of super abrasive machining for aeronautical applications in a multitasking machine.

This asset offers three fundamental services: first, research in multitasking machining, to carry out feasibility studies, testing, and improvement of applications in multitasking machining. The second service offers research in super abrasive machining, to carry out testing, training, and improvement of super abrasive machining applications aimed at the aeronautical industry. And finally, the third service offers research into new high-speed super abrasive tools, to carry out testing, training, and development of alternative manufacturing methods using super abrasive tools .

Through the BDIH Konexio program, LAIP has been able to access this UPV/EHU’s Research unit for superabrasive and multitasking machining and develop Smart toolholder for cryogenic-based alternative cooling in multitasking cells. LAIP is a tool holder manufacturer for machine tools for over 65 years, they offer both standard and customized clamping solutions reaching the 5 continents. They needed to be able to produce elements of high added value without using coolants, oils or emulsions. This means that starting from a cryogenic liquid, CO2 at very low temperatures, they feed this CO2 through this tool holder, and with this CO2 they are able to cool the tool, the part and the machining processes.

On BDIH’s website you will find more information about the Research unit for superabrasive and multitasking machining and you will be able to watch LAIP’s video where its manager, Jesus Echabe, and financier, Iñaki Lamarain, give you all the details.