Intelligent and connected machines: Defectology and surface-finishing

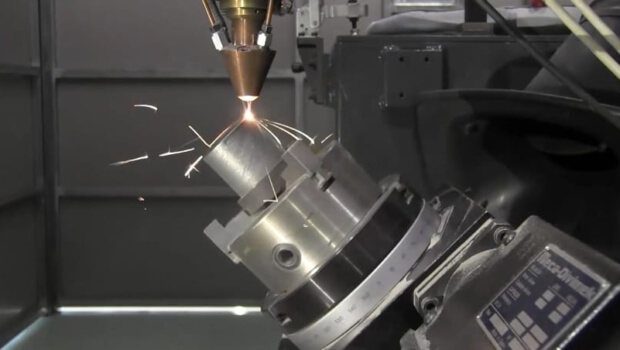

Defectology and surface finishing, are two of the most important aspects in the area of grinding. Some types of surface defects that generate rejection in machined parts are “lead error” and “waviness” resulting in a loss of precision in the manufactured parts, which is critical for companies in sectors such...

Women’s access, development and leadership in industry; strategic areas for the recovery from the impact of COVID-19

The manufacturing sector and the global economy have been seriously hit by the COVID-19 outbreak. However, a growing number of studies by international institutions, companies, trade union, academics and women's organisations highlight a crucial point: the pandemic's impact has not been gender neutral, as it has had different consequences for...

Intelligent and connected machines: Achieving value-add through improved Digital Finishing

Grupo SPRI presents the node of Intelligent and Connected Machines Node of the BDIH. A network of assets and experts with the purpose of placing the knowledge, solutions and tools for digital grinding at the feet of Basque industrial SMEs, to help them achieve optimum part finishes, implement stable, optimised...

Additive Manufacturing: A Relevant Enabler within Industry 4.0

In the photo, we present César Pérez, Technology Director of Lortek. This month dedicated to presenting the technological and human capacities of the Basque Digital Innovation Hub’s Additive Manufacturing node to the Basque industrial companies, closes with The Opinion of the Coordinator of the BDIH’s Additive Manufacturing Node, César Pérez....

ADDIMAT, an ideal partner for the BDIH

In the articles published to date, the SPRI Group, together with the BDIH, has presented the different nodes that make up the group, explaining their areas of action and highlighting the benefits that these can bring to the Basque industry through the implementation and use of 4.0 technologies. This article...

Aditive Manufacturing 4.0: FDM Technique

The techniques described in previous articles have focused on the development of additive manufacturing using metals and technologically complex techniques to obtain parts with difficult geometries. This time we will see that these advanced techniques can also be applied to another specific material: polymers. The processes are relatively analogous, while...

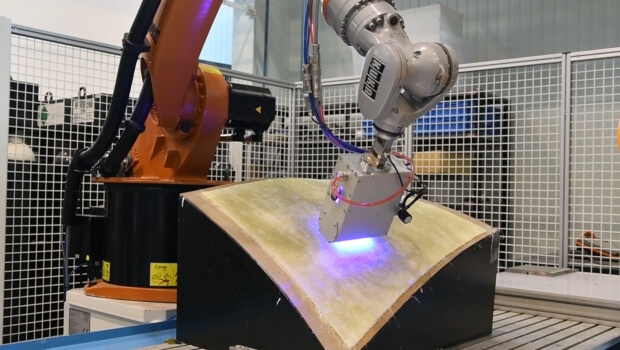

Additive Manufacturing 4.0: Laser Cladding

After highlighting two of the three main technologies in additive metal manufacturing, the time has come to present the latest technique: Laser Cladding. Laser Cladding consists of melting, directly, metallic powder, having previously projected it onto the surface of a base or substrate. Depending on its final use, or, saying...

Additive Manufacturing 4.0: Metal Fusion

Within the industrial landscape, the adoption of Additive Manufacturing is providing companies with innovative, customised and technologically advanced solutions to meet the shifting demands of their customers. By creating metallic objects by adding the material layer by layer, instead of using the techniques of casting, moulding, cutting and other traditional...

Additive Manufacturing 4.0: experiment and transform the way you conceive, design and manufacture your products

SPRI Group, together with the BDIH, presents the Additive Manufacturing node to Basque SMEs, a network of assets and experts focused on demonstrating to Basque industry the opportunity for incorporating new models, concepts and techniques in the production of existing parts and products. Additive manufacturing refers to manufacturing parts from...

The Closing word on…Advanced materials

Ibon Ocaña, European Business Development at CEIT. This month on advanced materials closes with some words from the coordinator of the Advanced Materials node of the BDIH, Ibon Ocaña. Ibon Ocaña holds a PhD in Engineering from the University of Navarra, and has an extensive and applied research career in...

The Basque Government participates in the Research and production project for the vaccine against COVID 19, together with Harvard and the company VIRALGEN

Tapia highlights that, once Harvard advances with the vaccine, the Basque Country is ready to take on this opportunity that represents a unique health, social and business advance

Materials 4.0: make your forging processes sustainable and energy efficient

In this article Grupo SPRI, together with the BDIH and its Advanced Materials Node, continues develop our knowledge and capacity to innovate metal manufacturing processes through forging technology, and in particular to the techniques and solutions that make them increasingly sustainable. In the previous article, we detailed how to use...

Materials 4.0: integrate composites into your design and manufacturing processes and drive the added value for your products

The SPRI Group, together with the BDIH and its Advanced Materials Node, describes in this article the technologies, solutions and services available for Basque companies to tackle the challenge inherent in replacing metal parts in their products with others made of composite or composite materials. Composites, as a term,...

Materials 4.0: Combine new and different materials to meet the challenge of manufacturing parts

In this article, SPRI Group, together with the BDIH and its Advanced Materials Node, shows manufacturing companies how to address the challenges of using different materials in the same part or structure and increase their product value, adapting both the processes of joining materials and the company’s own manufacturing...

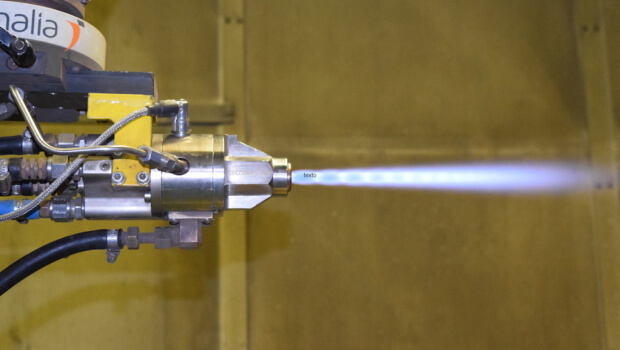

Materials 4.0: Three state-of-the-art surface modification techniques for your industrial components

This article details 3 techniques for modifying leading surfaces, which make it possible to significantly improve the characteristics of manufactured parts in aspects such as resistance to external agents (oxidation, corrosion, etc.), optimisation of friction and durability, and resistance to wear and tear, among others.

Materials 4.0: producing better performing, more durable and more sustainable products in the Basque Country!

The SPRI Group, together with the BDIH, makes the Advanced Materials Node available to Basque SMEs. The Node is a network of assets and experts working to show the opportunities for companies and demonstrating the value that advanced materials can provide to the Basque industry, especially in the automotive, metal...

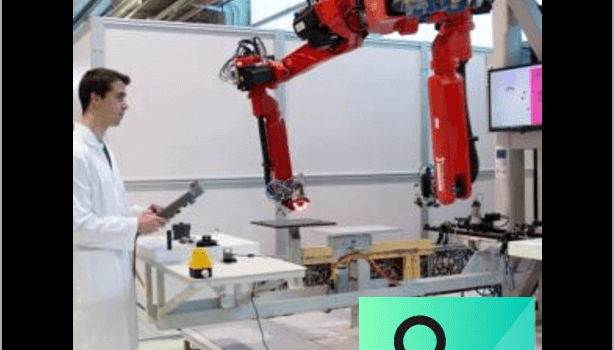

4.0 solutions: robotics for quality control

In this article from our “solutions 4.0” series we present the robots that provide the solution to specific needs in quality control of parts; from dimensional and surface control of produced parts using 2D/3D vision to integrity and defect control through 3D vision technologies, ultrasound and thermography. These technologies make...

4.0 solutions in robotics for manufacturing and assembly

The Basque Digital Innovation Hub, through its flexible and collaborative robotics node, attends to the industrial needs related to the manufacture and assembly of components, offering different solutions to companies that require specialized robots for the assembly, milling, deburring, drilling, screwing or reworking of parts, among other functions. These solutions...

VIVEbiotech SL new member of the Board of Directors of the Spanish Bioindustry Association (AseBio)

AseBio brings together more than 730 companies that employ almost 100,000 people and invest more than € 400 million in R&D

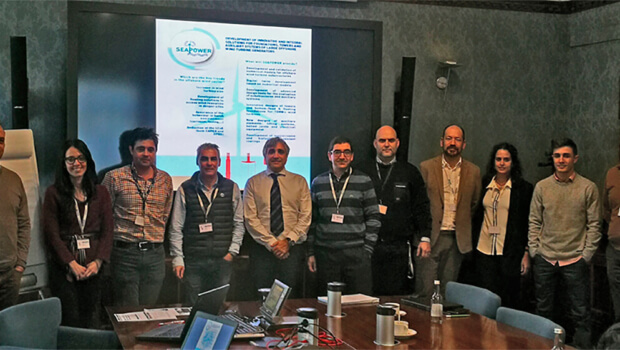

The Basque Seapower consortium will develop innovative solutions for the foundations, towers and auxiliary systems of high power offshore wind turbines

Seapower has a budget of €5.3M for 3 years, supported by the Basque Government's Hazitek Programme