Aludium invests 20 million euros in its Amorebieta plant

The group has announced the acquisition of a melting furnace capable of processing different types of scrap

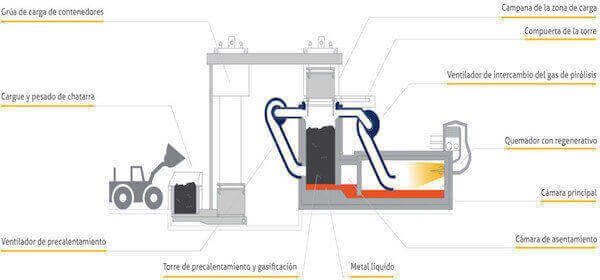

In order to boost its competitiveness, the Aludium metal company has announced that it will install a multi chamber melting furnace at its smelting plant in Amorebieta. The investment, involving 20 million euros, will allow the firm to create a more flexible production unit.

The new furnace system is capable of melting various types of scrap, including painted and lacquered, and this, together with the other equipment in the casthouse, will enable the company to create one of the most flexible metal production units in the world, according to a statement from the group.

Thanks to its advanced design, the furnace manages to reduce gas consumption and emissions of compounds like carbon dioxide and carbon monoxide, and has a throughput of 275 tonnes per day. In addition, once the furnace is fully operational, it is expected to be capable of processing 55,000 tons of scrap per day annually, thereby making the company less dependent on external suppliers.

The company expects installation work to be completed in 18 months and the furnace to be operational during the second half of 2019.

Aludium, a subsidiary of the US investment firm Atlas Holdings, is the entity that encompasses the former Alcoa factories in Spain and France. One of the group’s goals is to become the leading supplier of aluminium sheet, profiles and coils in Europe.

Related news

CIC biomaGUNE launches a company that will transform disease diagnosis by using nanosensors

Taldeki Biosolutions will be developing sensors for rapid, cost-effective, robust antibody detection, thus overcoming the stability and cost problems of current in vitro diagnostics

CIC nanoGUNE launches a new call: Industry Collaborative Research Positions

Programa honen helburua da ikertzaile profesionalak tokiko erakundeetan sar daitezen erraztea

Basque Open Industry will show Europe its industrial and technological ecosystem at the European SME Week (SME Week) from 13 to 17 November.

Talent, internationalisation, energy-environmental and technology-digital transitions. SME Week 2023. Exhibition and stands at the BEC: “Rebuild Ukraine”.

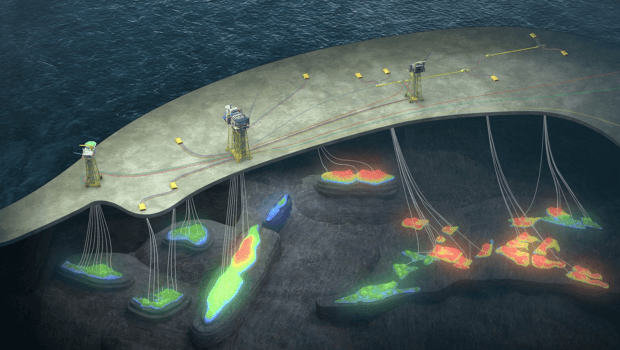

Aker Solutions selects TUBACEX as a delivery partner for umbilical tubes for key projects on the Norwegian Continental Shelf

An order intake for a sum of more than €70 million is one of the most significant deals in the umbilicals market. Solidifying TUBACEX’s technological position as a supplier of advanced industrial solutions for energy and mobility sectors.

65% of foreign companies established in the Basque Country plan to increase their turnover by 2023

Regard to the business climate, foreign capital companies in the Basque Country value the most the training of the workforce, the innovative environment, the available infrastructures and the Quality of Life

‘Syngoi Technologies’: Columbus VP creates a new company in Bizkaia for synthetic DNA production

Columbus VP, a venture capital investment management company with a singular focus on business opportunities emerging in the biotechnology and life sciences sector.

SPRI Group will propose at the World Manufacturing Forum transformative actions to enhance the presence of women in the manufacturing industry

Cristina Oyón has led the international group of experts that has drafted the report that will be disclosed on October 20th and 21st at the World Manufacturing Forum, which can be followed online for free upon registration

German company “FEV Consulting” opens an Operations Centre in Bilbao

With the support of the “Invest in the Basque Country” initiative, FEV Consulting opened an office in Bilbao in 2020.

The Basque Government participates in the Research and production project for the vaccine against COVID 19, together with Harvard and the company VIRALGEN

Tapia highlights that, once Harvard advances with the vaccine, the Basque Country is ready to take on this opportunity that represents a unique health, social and business advance

The Financial Times ranks the Basque Country as the most attractive medium-sized European region in its strategy to attract foreign investment

fDi Intelligence magazine, a specialist division from the Financial Times group, highlights the efforts of the SPRI Group in attracting investment for the fourth time in a row