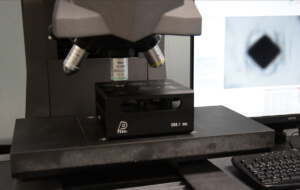

Tecnalia’s Manufacturing laboratory highly productive in composites is one of the assets of BDIH’s Advanced materials node. The laboratory applies advanced technologies to the different stages of composites manufacturing: cutting, stacking, wrapping, preformed 3D, fast warming and efficient tools, 4.0 processes and automatization solutions.

Through the BDIH Konexio program, Composites Martiartu has been able to access this Tecnalia’s Manufacturing laboratory highly productive in composites and develop a Prospective of “Sheet Molding Compounding” technologies. Composites Martiartu is located in Arrigorriaga in the Martiartu Industrial Park. The company was born in the 2000 as Mecanizados Martiartu. Initially they were dedicated to the machining of thermosets, thermoplastics and small assemblies. In these more than 20 years they have multiplied by 10 the initial staff. They are specialized in manufacturing of SMC parts, for sectors such as transport, electrics, telecommunications, construction, automotive and railway. In recent years we have grown both in the number of people employed and in facilities. For these two reasons they considered essential to bet on production methods according to Industry 4.0, which would allow them to adjust their costs to the maximum, and stay aligned with their objectives of entering these highly competitive markets.

On BDIH’s website you will find more information about the Manufacturing laboratory highly productive in composites and you will be able to watch Composites Martiartu’s video where its manager, José Ramón Alonso and his team, give you all the details.

8 February, 2023 BDIH

8 February, 2023 BDIH 1 February, 2023 BDIH

1 February, 2023 BDIH 21 December, 2022 BDIH

21 December, 2022 BDIH 14 December, 2022 BDIH

14 December, 2022 BDIH 25 May, 2022 BDIH

25 May, 2022 BDIHFor SMEs, for diversifying markets, internships abroad, international tenders, non-reimbursable subsidies to consolidate exports, subsidies for deployments or specific training in internationalisation.

You’re interested, right?