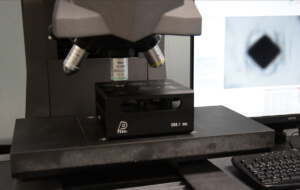

Nowadays, a large part of industrial processes are evaluated using destructive techniques. These are processes where the only way to determine if a part has the appropriate mechanical properties is to cut it up, look at it under a microscope, and throw it away for scrap.

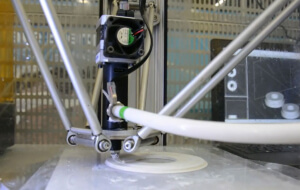

Thanks to this asset, Basque companies can avoid the damage replacing the process with a system for measuring magnetic properties to obtain information on the microstructural or mechanical characteristics of ferromagnetic parts in an indirect way. Likewise, the asset will allow non-destructive tests to be carried out in order to obtain information on the properties of steels and detect production defects such as variations in surface hardness, grinding burns, residual stresses or a hardened layer. Businesses will also benefit from the fact that this system will be able to perform both manual and automatic measurements by using a robot and that different types of sensors can be attached to it, depending on the geometry and characteristics of the part to be tested.

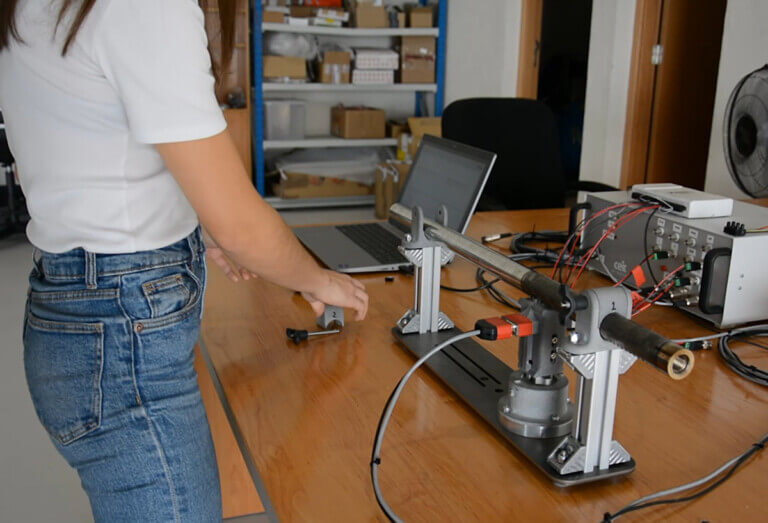

Linqcase has used this asset in oder to develop a headboard and its associated electronics to detect grinding burns on motor shafts, mainly on ferromagnetic parts.

Linq is a company founded in 2018 with the idea of reducing the metal scrap produced in manufacturing. Through this asset of CEIT, the company has been able to open up to other sectors and grow internationally.

Do not miss the video of Linq, where its CEO, Ibon Iribarren, and its Engineering Director, , Ángel Iglesia, will explain all the details of this case and the benefits obtained.

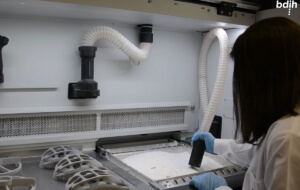

Another of the success stories related to the use of this asset has been that of the company Fagor Electrónica. They have managed to develop and design a new die that helps them in the stamping or drawing process of sheet metal forming. This means an improvement in the handling of materials and optimisation of the drawing process.

Fagor electrónica was founded in 1957 and has more than 650 employees. They design and manufacture automated and high-tech lines for the sheet metal sector, forming lines for the automotive sector, cutting lines for the steel value chain and manufacturing lines for the domestic appliance sector.

Don’t miss the Fagor video where the head of Corporate Innovation, Andoitz Aramburu, and the research professor at Mondragon Unibertsitatea, Lander Galdós, explain how they have applied this asset in their company and the benefits obtained.

8 February, 2023 BDIH

8 February, 2023 BDIH 1 February, 2023 BDIH

1 February, 2023 BDIH 21 December, 2022 BDIH

21 December, 2022 BDIH 25 May, 2022 BDIH

25 May, 2022 BDIH 12 May, 2022 BDIH

12 May, 2022 BDIHFor SMEs, for diversifying markets, internships abroad, international tenders, non-reimbursable subsidies to consolidate exports, subsidies for deployments or specific training in internationalisation.

You’re interested, right?